|

Zhejiang Jiangnan Pharmaceutical Machinery Co.,Ltd.

|

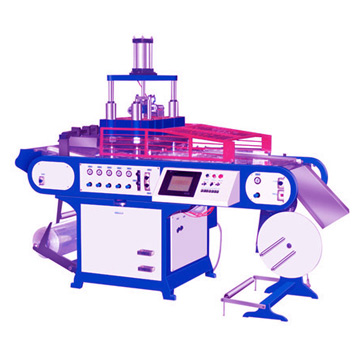

BOPS Auto Baric Thermoforming Machines

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Minimum Order: 1 unit

Payment Terms: L/C, T/T

Features:

1) 580 x 520

2) High-efficiency, auto baric heating molding machine equipment, which

Minimum Order: 1 unit

Payment Terms: L/C, T/T

Features:

1) 580 x 520

2) High-efficiency, auto baric heating molding machine equipment, which we adopt

the newest international technique to develop

3) The machine can send-sheet, heating, molding, incise side

4) Cycle: 3-5s

5) Used to machining BOPS, PVC, HIPS, PET and other plastic sheets

6) Designed with engine, electricity and gas

7) Microcomputer controls

8) Has manpower, half-auto, auto three functions

9) The equipment's gas and electricity element is made in Japan, Germany in order to

ensure stability and reliability

10) Heating board is high-grade alloy steel made in Switzerland

11) Made by especial quenched technique

12) Rigidity can reach 63 degrees

13) Auto designed warm-up function shortens an hour, so that production has

improved 12%

14) Can produce all kinds of plastic vessel used by one time and other plastic

production

15) As plastic containers of ice-cream, cooling drinks, yogurt, containers, all kinds of

tins, preserved fruits, pickles, candies, chocolate, cakes, snacks, all kinds

of green stuff, as well as different kinds of packages of fishery, medicine,

toy, tittle hardware, dress, and other commodities

Specifications:

1) Max. shaping size: 580 x 520mm

2) Max. shaping depth: 100mm

3) Max. width of flat: 660mm

4) Thickness of flat: 0.15-1mm

5) Max. diameter of flat roll: 710mm

6) Max. length of mould cut: 635mm

7) Air pressure: 0.7MPa

8) Power of pre-heater: 4kW

9) Power of mould heater: 4.8kW

10) Power of heater: 12kW

11) Electriciy supply: 380V15%

12) Water consumption: 350L/h

13) Production speed: 600-1200s/h

14) Overall size: 3200 x 1400 x 2350mm

15) Total weight: 2.3MT

16) Max. air flow: 2m3/min

Payment Terms: L/C, T/T

Features:

1) 580 x 520

2) High-efficiency, auto baric heating molding machine equipment, which we adopt

the newest international technique to develop

3) The machine can send-sheet, heating, molding, incise side

4) Cycle: 3-5s

5) Used to machining BOPS, PVC, HIPS, PET and other plastic sheets

6) Designed with engine, electricity and gas

7) Microcomputer controls

8) Has manpower, half-auto, auto three functions

9) The equipment's gas and electricity element is made in Japan, Germany in order to

ensure stability and reliability

10) Heating board is high-grade alloy steel made in Switzerland

11) Made by especial quenched technique

12) Rigidity can reach 63 degrees

13) Auto designed warm-up function shortens an hour, so that production has

improved 12%

14) Can produce all kinds of plastic vessel used by one time and other plastic

production

15) As plastic containers of ice-cream, cooling drinks, yogurt, containers, all kinds of

tins, preserved fruits, pickles, candies, chocolate, cakes, snacks, all kinds

of green stuff, as well as different kinds of packages of fishery, medicine,

toy, tittle hardware, dress, and other commodities

Specifications:

1) Max. shaping size: 580 x 520mm

2) Max. shaping depth: 100mm

3) Max. width of flat: 660mm

4) Thickness of flat: 0.15-1mm

5) Max. diameter of flat roll: 710mm

6) Max. length of mould cut: 635mm

7) Air pressure: 0.7MPa

8) Power of pre-heater: 4kW

9) Power of mould heater: 4.8kW

10) Power of heater: 12kW

11) Electriciy supply: 380V15%

12) Water consumption: 350L/h

13) Production speed: 600-1200s/h

14) Overall size: 3200 x 1400 x 2350mm

15) Total weight: 2.3MT

16) Max. air flow: 2m3/min

Related Search

Bops Forming Machines

Plastic Cup Thermoforming Machines

Thermoforming

Thermoforming Machine

Bops Food Container

Bops Plastic Tray

More>>